Almost every known fluid in industry through the world can be, and is , handled by the diaphragm valves.

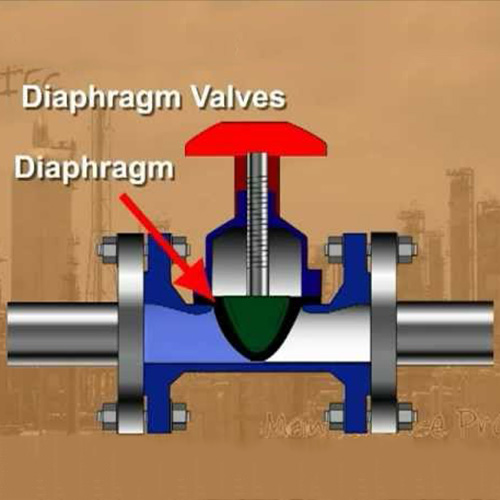

The basic construction of the Diaphragm valve is quite simple. It is composed of three principal units called Body, Bonnet and Diaphragm.

Diaphragm valves are particularly suitable for service lines handling Corrosive, Abrasives, Viscous or Fibrous Fluids.

There are numerous combinations available for slecting the most siutable body material, body lining and diaphragm material for a specific service depends on several variables, economic considerations nature of fluid handled, its concentration and corrosiveness,temperature,pressure,velocity and continuity of flow.

Flanged Ends- Cast Iron, Carbon steel, Stainless Steel (CF8,CF8M) sizes: DN 15- DN 300.Flanged End Cast Iron Lined- Natural Rubber, White Natural Rubber, Neoprene, Hypalon,Black Butyl, White Butyl, BunaN,Ebonite. Sizes:DN 15- DN 300.

Diaphragm life depends not only upon the nature of the fliud handled but also upon the temperature, pressure and frequency of operations.

Diaphragms can be moulded in wide variety of compounds, to give most satisfactory results, depending upon application.ROYALTECH VALVES elastomer diaphragms are marked with materials identification, vlave size, month and year of manufacture.